| 3D PRINTING AND DESIGN REFERENCE DOCUMENT |

|

|---|---|

| Document Title: | Designing Better Looking Faceplates for 3D Printing |

| Document No.: | 1728994779 |

| Author(s): | jattie |

| Contributor(s): | |

REVISION HISTORY

| Revision | Details of Modification(s) | Reason for modification | Date | By |

|---|---|---|---|---|

| 0 | Draft release | Desingn for 3D printing | 2024/10/15 12:19 | jattie |

Multi Colour Faceplate Designs

This topic came up working on a various projects that required a faceplate, like a clock face, a ruler or the faceplate for a sundial.

The idea is to use a printer with multi material capabilities (MMU or AMS) and design prints to exploit these features for the best possible results using FDM 3D printing techniques.

The traditional methods employed is to either emboss of deboss and with multi colour printers we just stated “paining” into the embossed or debossed parts. This approach is to have the letters and numbers as separate objects on equal height, but printed in different colours. Separate objects simply paints cleaner with clear boundaries.

CAD Design Approach

The obvious way is to emboss or slice a surface and paint the layers in using slicers. One very elegant solution is to create the parts you want to see as separate objects.

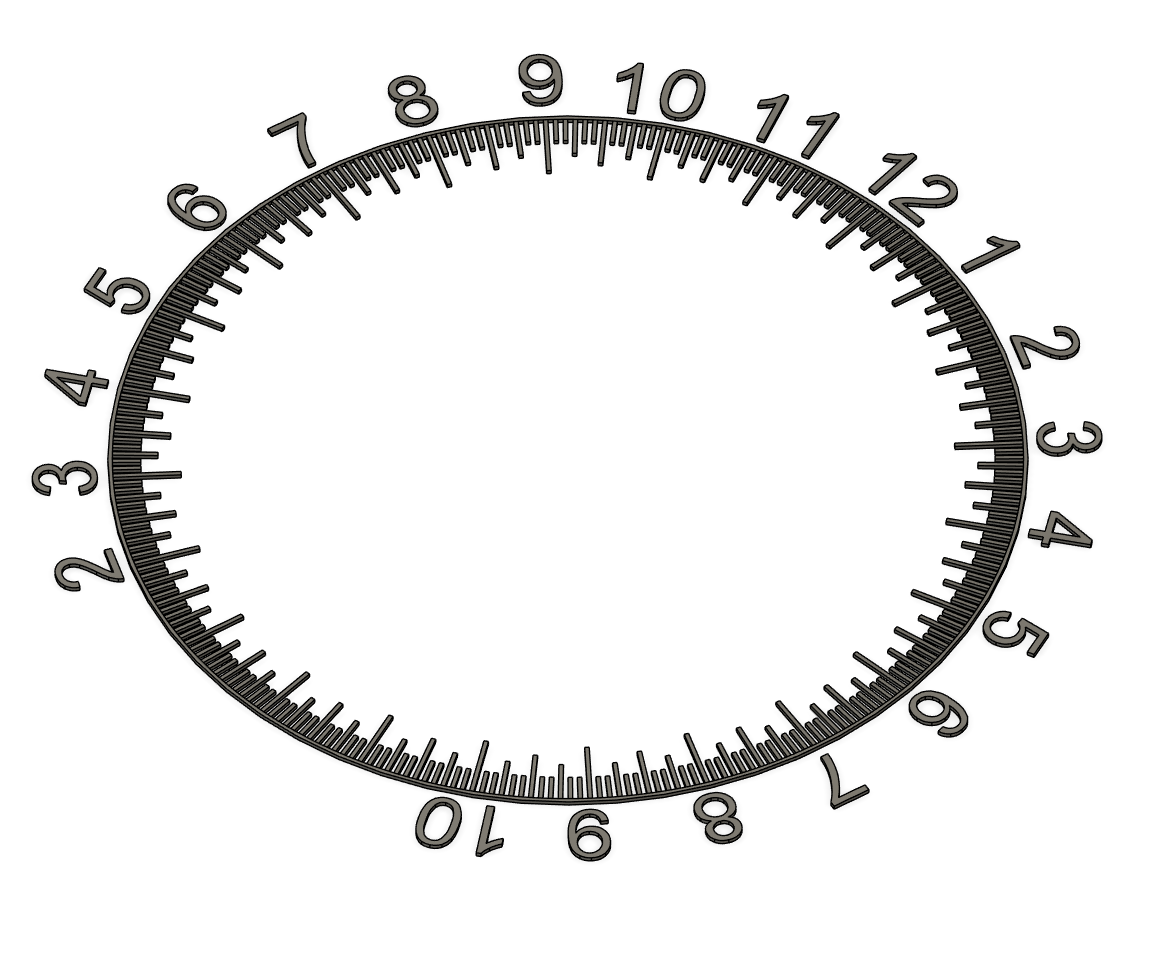

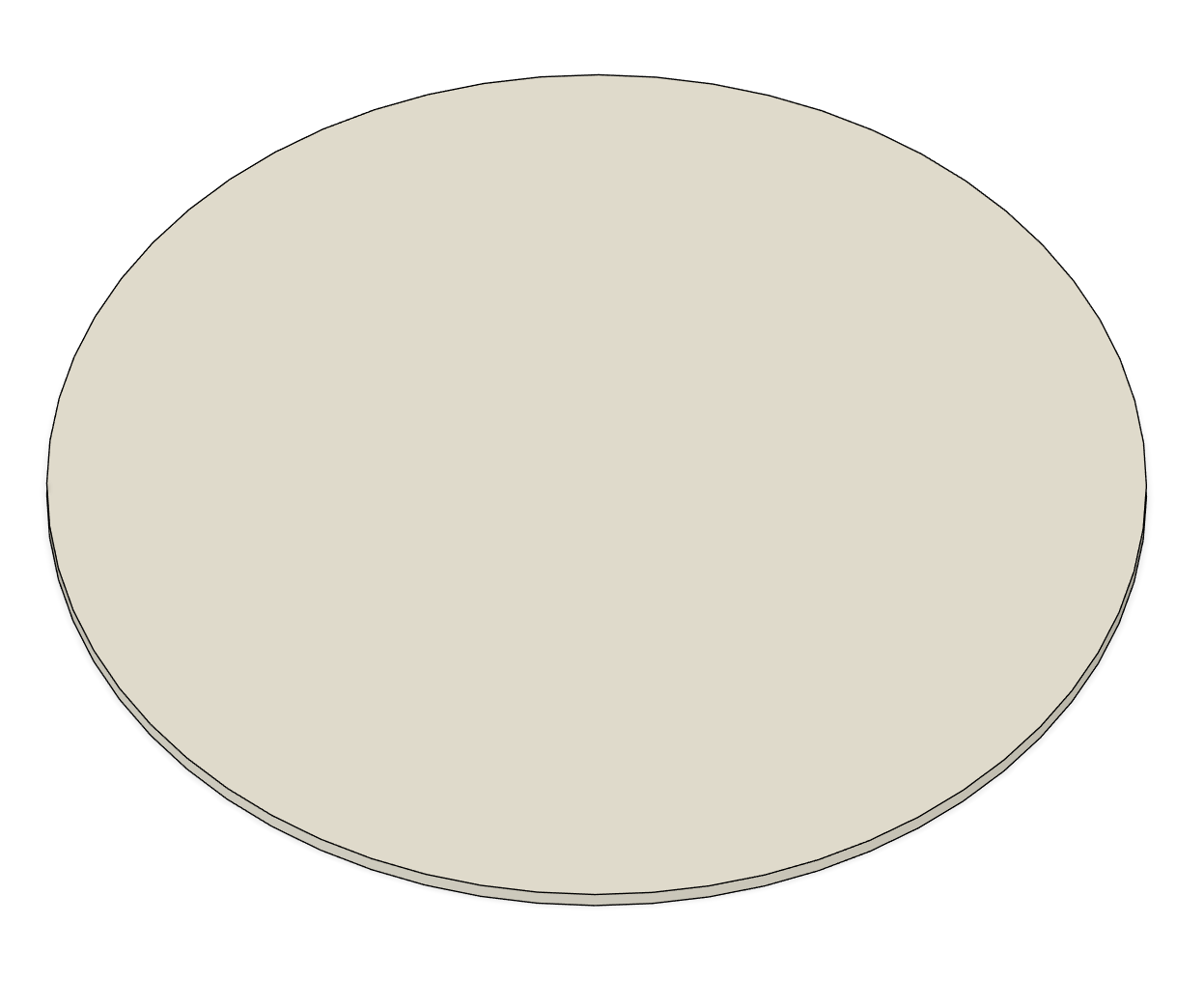

Then create the faceplate on the same layer, extruding downwards to create a thicker body that the parts in step one, for example, the numbers and lines in part one I created is 0.8mm deep, so will be four layers deep with a print height set at 0.2mm. The Faceplate body I extruded to 3mm.

The next step the using the numbers and dial indicators cut the faceplate and keep the parts you're cutting with.

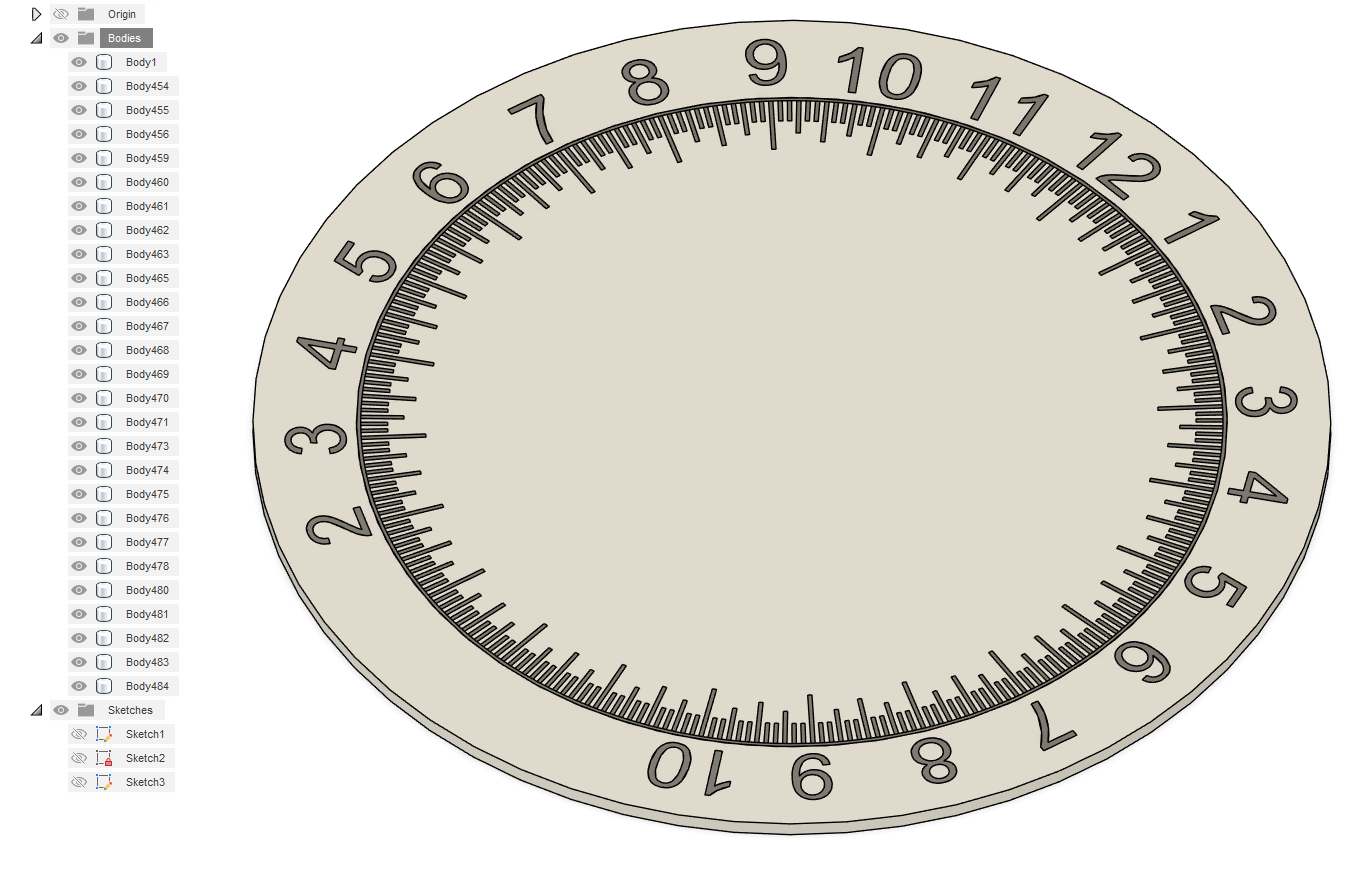

This results in many bodies with letter cut into the faceplate but at the exact same height.

The next step is to export all the parts as one file to use in the slicer.

This is an important step for we need all the parts in the slicer in it's right positions. For Fusion360 the process looks like this. It creates a .stl file that can be slices with all the parts in it's positions.

Slicer Treatment

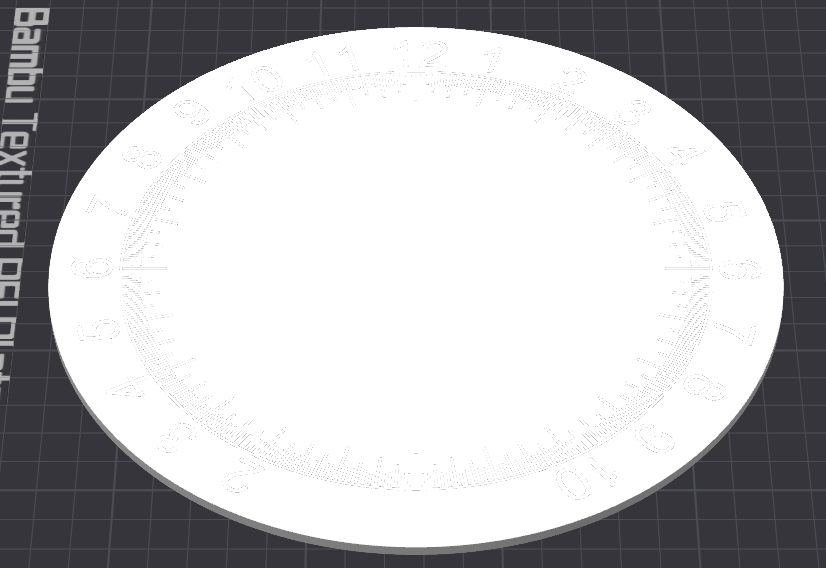

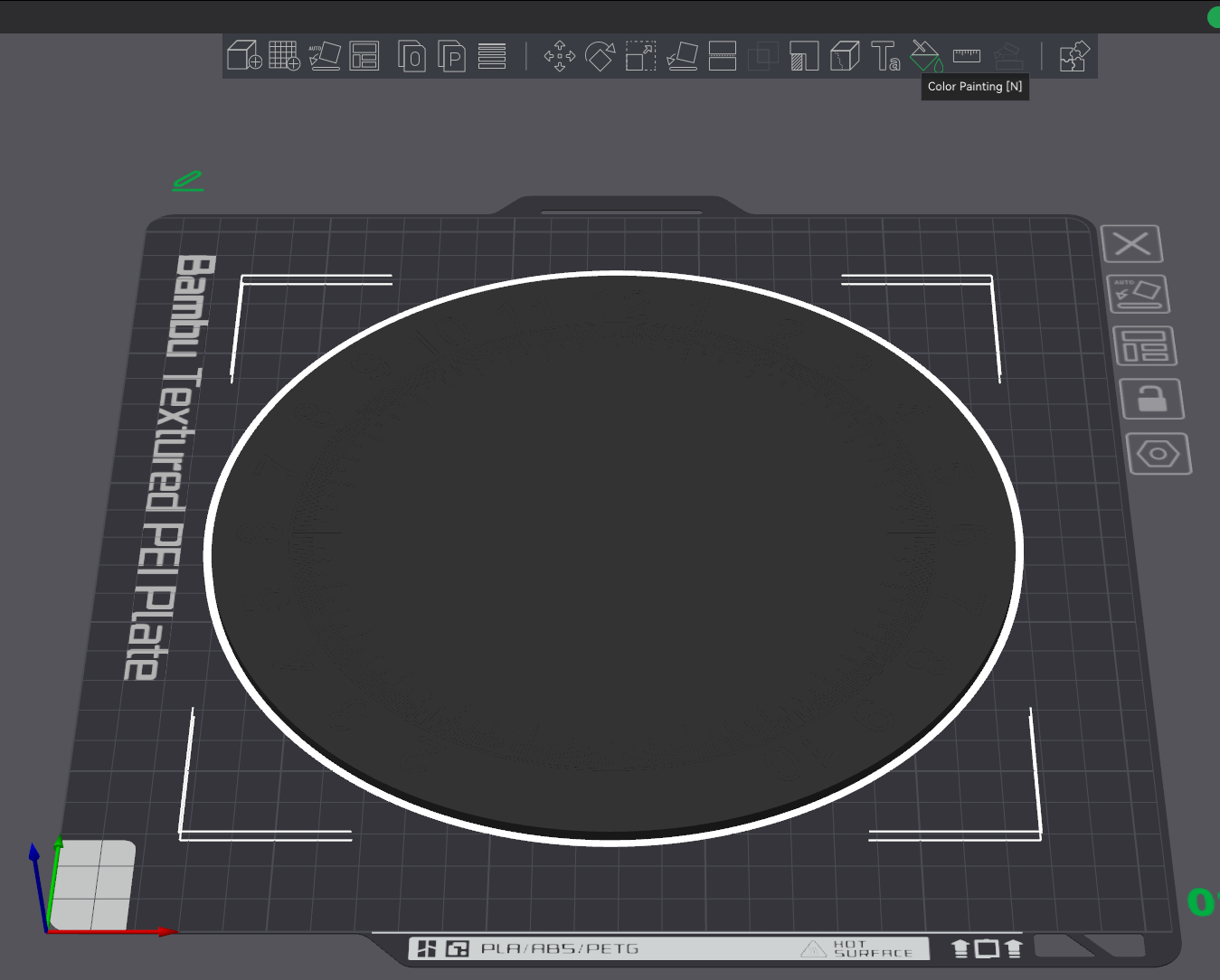

I am using Orca slicer and Bambu Studio. The first step importing it into a slicer it looks like this.

I then change the default filament to black and then proceed to paint in the faceplate white.

Select the fill paint style and paint colour.

Paint all the white parts in including the sides and bottom until it looks like the third image.

Even Better Surface Print Quality

For even better print quality I flip the image upside down.

Printing like that leaves my texture build plate impressions on the top surface resulting in a really professional looking result.